Fan EPS mould Air Blower Styrofoam Mold Air-blast Sprayer Air Turbine Aluminum Mold

Fan EPS mould Air Blower Styrofoam Mold Air-blast Sprayer Air Turbine Aluminum Mold

Product Name:

Fan EPS mould, Aluminum mold

Category:

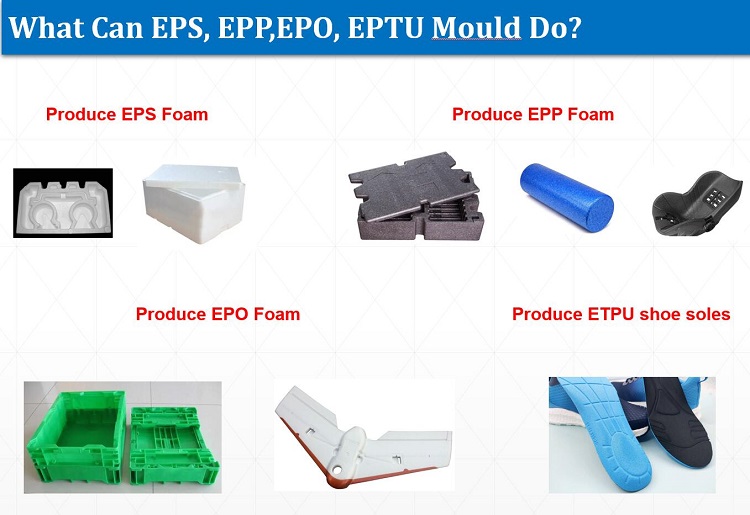

EPS(styrofoam) mold,EPP mold,EPO mold

Application:

Packing industry, Home appliance,Consumer Electronics,Toys, Furniture, Aeromodelling, Sporting and etc.

Advantage:

It Reduced Weight:

the mould is made of Aluminum, it is much lighter than steel.

Strengthened:

The foam-like structure produced by foaming moulding makes plastic items stronger and more rigid. As a result, products may be more durable and last longer.

Short Lead Time:

only 15-20 days to finish one set of mould.

Improved Thermal Insulation:

Plastic components can improve their thermal insulation capabilities by having a foam-like structure formed by the foaming moulding process.

Reduced Shrinkage:

Gas can be added during the foaming moulding process to help minimize shrinkage, producing more accurate and exact components.

Cost-effectiveness:

This moulding can lead to cost savings since it uses less material, has a faster cycle time, and produces a better product. Due to the decreased weight of the produced plastic pieces, it can also save shipping costs.

Eco-friendly:

Foaming moulding is also environmentally friendly since it uses less material and produces less waste.

Contact: Gabriel PH

Phone: +86 18681086170

E-mail: info@precision-mold-parts.com

Add: No. 2, 8 Hongye North Road, 138 Industrial Zone, Tangxia Town, Dongguan, Guangdong, China